Explosion Proof Aerial Lifts

Bailey Develops Next Generation Explosion-Proof Aerial Work Platforms

As developers of the original EX Series Explosion-Proof lifts back in 2002, many things have changed including ANSI Standards and better Intrinsically Safe Technology. The original EX technology was developed under Man Lift Engineering, Bailey’s first company which was sold in 2010. Every major aircraft manufacturer in North America utilized these lifts as well as many ship and general industrial painting operations.

As developers of the original EX Series Explosion-Proof lifts back in 2002, many things have changed including ANSI Standards and better Intrinsically Safe Technology. The original EX technology was developed under Man Lift Engineering, Bailey’s first company which was sold in 2010. Every major aircraft manufacturer in North America utilized these lifts as well as many ship and general industrial painting operations.

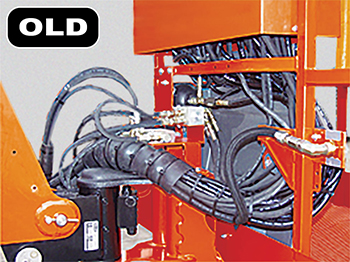

While the original technology served its purpose, advances in EX technology have made earlier systems obsolete. Complicated hydraulic systems resulted in extensive use of hydraulic hoses which caused many leak points and resulted in a maintenance nightmare. Better motor switching technology results in longer life and reduced maintenance.

The original ANSI standards in 2002 was A92.5 followed by A92.6. and the current ANSI standard is A92.20. The most significant change is platform load sensing. The ability to sense the load in the platform and stop functions for safety. Our news systems incorporate this load sensing technology compliant with EX explosion-proof standards.

New EX Boom Lift Technology

Competition’s Platform Control Box

Bailey’s Platform Control Box

The competition still uses hydraulic joysticks requiring many hoses to route through cable tracks to the platform. Hydraulic joysticks have been replaced by electric over 20 years ago due to the maintenance and leakage nightmare. The competition has 27 hoses and 38 fittings at the platform. A high pressure hydraulic leak or blown hose could ruin a paint job!

NFPA/NEC 70 Electrical Requirement changes. Our latest certifications include the new requirements of special metal shielded cabling.

Competitors Design: Still using SOOW rubber shielded cables which is “Non-Approved” by the latest changes. If an incident occurs, everyone is liable for noncompliance.

Factory Mutual Certification now requires Anti-spark wheel covers. Our products include these new requirements.

Competitors Design: Does not provide and is not compliant with latest FM requirements.

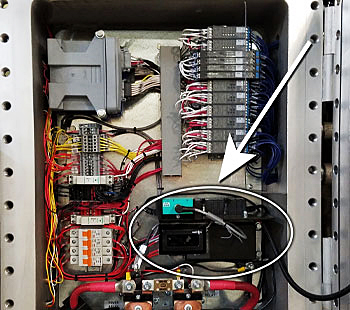

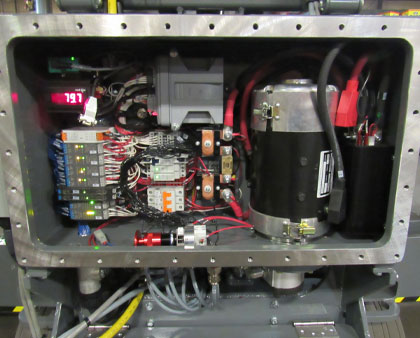

Enhanced Motor Management System

Provides improved control of motor operation. Motor contactors are controlled with a more stable signal resulting in improved life and better machine operation.

Competitors Design: Contactors powered by 24V battery pull-off resulting in uneven battery charge condition and contactor flutter at low battery conditions.

New EX Scissor Lift Technology

NFPA/NEC 70 Electrical Requirement changes. Our latest certifications include the new requirements of special shielded cabling.

Competitors Design: Still using SOOW rubber shielded cables which is “Non-Approved” by the latest changes. If an incident occurs, everyone is liable from noncompliance.

Enhanced Motor Management System Provides improved control of motor operation. Motor contactors are controlled with a more stable signal resulting in improved life and better machine operation.

Competitors Design: Contactors powered by 24V battery pull-off resulting in uneven battery charge condition and contactor flutter at low battery conditions.

Factory Mutual Certification now requires Anti-spark wheel covers. Our products include these new requirements.

Competitors Design: Does not provide and is not compliant with the latest FM requirements.

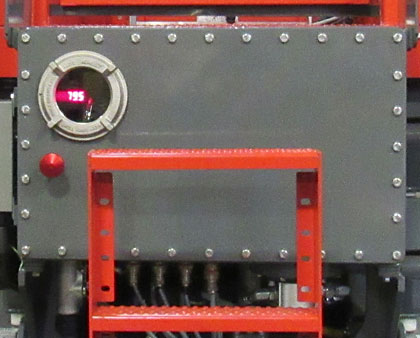

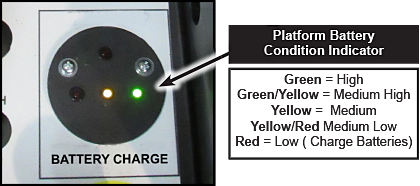

Competitors Design: Battery Condition Indicator located at ground only away from operator. What would happen if machine stopped in the middle of a painting operation?

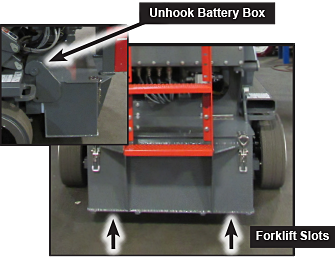

Battery can be quickly removed with forklift for continued multi shift operations.

Control system failure on competitors design would result in hours to repair as compared to minutes with ours.

Competitors Design: Competitive product requires crane for removal of canister and disassembly on bench.

The control system includes circuit breakers in place of glass fuses. The circuit breakers can be easily reset if a problem occurs.

Competitors Design:: Competitors design uses glass fuses that require replacement.

Why Bailey?

Not just experts on EX technology, Bailey has a long history of building custom Aerial Work Platforms for a variety of industries. The backbone of our expertise is extensive Standards involvement including past committee memberships on the following:

- ANSI A92.5 Boom Supported Elevating Work Platform

- ANSI A92.6 Self-Propelled Aerial Work Platforms

- NFPA 505 Fire Safety Standards (Explosion-proof) for Industrial Trucks

- UL 583 Safety Standards - Battery Powered Industrial Trucks

- UL 588 Safety Standards - Internal Combusion Engine Industrial Trucks

When building or modifying Aerial Work Platforms there are strict, well defined safety requirements that cannot be overlooked. These include stability analysis, stress analysis and control system functional safety. Bailey is expert in all of these fields. Others in the industry appear to have experience in EX technology but are not Aerial Work Platform experts. These are questions that they often have trouble answering: Do their modifications affect machine stability? Do their control system modifications meet the ANSI requirements? Raising personnel 80 feet in the air has significantly more Safety Risk as compared to modification of a forklift. The Safety Risk is great. Another competitor was recently sold to a fabrication house thinking that building off a set of drawings is good enough. Not having extensive EX experience is a Safety Risk.

The Engineers at Bailey have been involved in the development of the following products:

- Clean Room lifts at Cape Canaveral preparing satellites for launch up to 135’ sold to United Launch Alliance.

- Aircraft painting EX lifts sold to Boeing, Lockheed Martin, Northrop Grumman, Bombardier and Gulfstream.

- Specialized lifts building aircraft for Boeing and Spirit Aerospace.

- Rocket Launch Platform, Up Aerospace – The first commercial launch company located at Spaceport America.

EX Explosion Proof Booms

EX Articulating Booms:

| Model | Working Height | Lift Capacity | Specifications |

|---|---|---|---|

| AE30JEX | 36 ft [10.97 m] | 500 lbs [227 kg] | View |

| AE45JEX | 51 ft [15.5 m] | 500 lbs [227 kg] | View |

| A45JEX | 51 ft [15.5 m] | 500 lbs [227 kg] | View |

| A60EX | 66 ft [20.11 m] | 1,000 lbs [454 kg] | View |

| A60JEX | 66 ft [20.11 m] | 500 lbs [277 kg] | View |

| A80EX | 86 ft [26.21 m] | 1,000 lbs [454 kg] | View |

| A80JEX | 86 ft [26.21 m] | 500 lbs [227 kg] | View |

EX Telescopic Booms:

| Model | Working Height | Lift Capacity | Specifications |

|---|---|---|---|

| T40EX | 45 ft [13.72 m] | 1,000 lbs [454 kg] | View |

| T46JEX | 52 ft [15.85 m] | 500 lbs [227 kg] | View |

| T60EX | 66 ft [60.12 m] | 1,000 lbs [454 kg] | View |

| T66JEX | 71 ft [21.64 m] | 750 lbs [340 kg] | View |

| T80EX | 86 ft [26.21 m] | 1,000 lbs [454 kg] | View |

EX Vertical Booms:

| Model | Working Height | Lift Capacity | Specifications |

|---|---|---|---|

| MVL15EX | 20 ft [6.1 m] | 500 lbs [227 kg] | View |

| MVL20EX | 25 ftn [7.62 m] | 350 lbs [160 kg] | View |

EX Explosion Proof Scissors

EX Scissors:

| Model | Working Height | Lift Capacity | Specifications |

|---|---|---|---|

| 1532EX | 21 ft [6.4 m] | 550 lbs [272 kg] | View |

| 1932EX | 25 ft [7.6 m] | 550 lbs [250 kg] | View |

| 2032EX | 26 ft [7.9 m] | 900 lbs [408.3 kg] | View |

| 2047EX | 26 ft [7.9 m] | 1,300 lbs [591 kg] | View |

| 2632EX | 32 ft [9.8 m] | 500 lbs [227 kg] | View |

| 2647EX | 32 ft [9.75 m] | 1,000 lbs [454 kg] | View |

| 2668EX | 32 ft [9.8 m] | 1,200 lbs [545 kg] | View |

| 3247EX | 38 ft [11.6 m] | 700 lbs [318 kg] | View |

| 3268EX | 38 ft [11.6 m] | 1,000 lbs [454 kg] | View |

| 3392EX | 39 ft [11.89 m] | 2,750 lbs [1,247 kg] | View |

| 4047EX | 45.5 ft [13.8 m] | 770 lbs [227 kg] | View |

| 4392EX | 49 ft [14.98 m] | 2,000 lbs [907 kg] | View |

| 5392EX | 59 ft [17.98 m] | 1,500 lbs [680 kg] | View |

Competitors Design: Battery Condition Indicator located at ground only away from operator. What would happen if machine stopped in the middle of a painting operation?